The Fundamentals of Moisture Calibration

Why humidity calibration is important

Reputable manufacturers will provide calibration certificates with instruments or sensors at the time of purchase. However, this is not a guarantee of the measurement performance throughout the entire lifetime of the equipment. Over time, the ageing of mechanical and electronic components can cause changes in the characteristics of sensor or instruments. More critically, once the device has been used in the field, and possibly introduced to contaminants which can have an impact on accuracy, it is difficult to say with any degree of certainty whether or not the original calibration is still valid.

How is the calibration data used?

When the readings provided by the sensor or instrument are critical to a process or testing procedure, it is vital to know that the device is still performing within its original specifications, or if the correction factors have changed. When an instrument is recalibrated, a report is provided showing the calibration corrections before and after any adjustment was performed. For many hygrometer users, these ‘readings before’ are crucial, as they can be retrospectively applied to readings taken in the period before calibration.

In order to minimise uncertainty and have confidence in measurements made with the instrument, it is important to have the quality assurance of a regular, accredited calibration procedure.

What is humidity calibration?

Calibration is the process of comparing a measuring instrument against an authoritative reference to identify any bias or systematic error in the readings. The reference instrument in any calibration should ideally be at least 10 times as accurate as the instrument under test to avoid the tolerances of the reference influencing whether the test instrument is classed as a ‘pass’ or ‘fail’. Generally, a calibration will be performed by repeating the process of comparison at a representative selection of points across the measurement range.

Calibration is often interpreted as ‘adjustment of an instrument to read correctly,’ but this is a misconception. Adjustment of an instrument to match a calibrated reference is a separate concept. It is a process which is usually carried out by an equipment manufacturer by internally applying the calibration corrections to bring the output readings into line with the indications of the calibration reference.

Calibration Standards and Traceability

The best way to ensure accuracy of measurement is through traceability to attested standards.

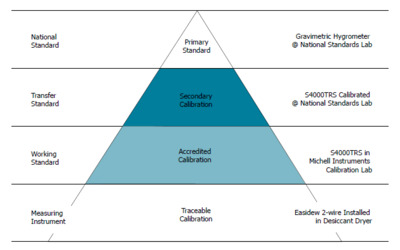

This leads to consistency of measurements across different instrumentation, locations and users. ‘Traceability’ is an unbroken chain of calibrations which relate a working hygrometer back to a national standard.

Most countries hold their own authoritative national standard for dew point and humidity, which forms the primary measurement standard. Alternatively, reference standards are shared across a region. The reference instruments of calibration facilities in the country or region are calibrated against this primary standard, and are then used as references or ‘transfer standards’ to calibrate other instruments.

This approach is represented by the pyramid graphic below (Figure 1).

How is a Humidity Calibration Carried Out?

Humidity calibrations involve generating a stable level of humidity in a sample gas and measuring this with both a suitable fundamental reference instrument and the instrument under calibration, then making a comparison of the readings.

A humidity calibration system comprises of:

- A dry air source

- A humidity generator to provide the desired moisture content

- A reference instrument which is more accurate than the instrument under test to provide an authoritative measurement

- A manifold to supply calibration gas to the sensors/instruments under test

If the calibration is being performed in terms of relative humidity and temperature, then the manifold must be temperature controlled or placed in a temperature-controlled environment in order to determine the relative humidity by associating the generated dew-point value with the temperature.

Michell Instruments is the only supplier to offer complete dew-point calibration systems and individual calibration components, all of which are designed and built in-house.

A Typical Calibration Certificate

A calibration certificate will contain a table with a list of calibration points:

The 1st column shows the measured value indicated by the reference instrument.

The 2nd column shows the measured value indicated by the instrument under calibration.

The 4th column shows the correction that should be applied to any measured values obtained from the instrument under calibration.

Generally, if the instrument under calibration has multiple ways to report the measured value, (i.e. built-in display, digital output, analog voltage or current outputs), then the values taken from these different outputs will also be shown on the certificate at each calibration point.

Other information that should be included on the calibration certificate is:

- Customer details, sometimes including the customer’s address, customer number or order number

- Any serial numbers that identify the instrument and associated measuring components

- The date of the calibration, and sometimes the date when the subsequent calibration is due

- A unique reference number identifying the certificate or calibration run

- A list of calibrated equipment used during the calibration, or a list of unique identifiers corresponding to that equipment

- An estimation of uncertainty over the range of the calibration

In-House Calibration vs. External Calibration

Meteorological organisations, standards laboratories, pharmaceutical manufacturing plants and other businesses or institutions that operate many calibrated instruments or sensors must have an effective calibration system in place. It is usually more sensible to perform calibrations in-house, rather than managing the cost and downtime (or availability of replacement calibrated sensors) associated with sending equipment away to an external commercial calibration laboratory.

However, purchasing and operating a dedicated humidity calibration system can be a significant commitment in terms of initial cost, personnel training, record keeping and in some cases physical space. For companies that use a small number of humidity instruments, sending these to a commercial calibration laboratory for regular calibration is the most cost-effective solution.

Wannon Water Solves Pump Blockage Issue

Wannon Water replaced some old digester pumps at its Hamilton wastewater treatment plant with new...

Gippsland Water eliminates pump blockages at Morwell WWTP

At the Gippsland Water Morwell Waste Water Treatment Plant, the company have utilised two Gorman...

Sydney Water replaces actuators to ensure clean drinking water

Replacing hydraulic actuators with electric actuators from AUMA ensures drinking water is free...