Have you ever thought of a wastewater treatment facility as a power plant?

Moving a step closer towards net zero energy consumption, products have been developed by Evoqua to help meet emerging water and energy issues.

The Captivator™ System: for activated sludge plants with anaerobic digestion

Captivator is a system enhancement that stretches every KW using a unique front-end set-up including an aerated contact tank followed by dissolved air flotation. When combined with anaerobic digestion and energy recovery technology, it allows a facility to potentially become energy positive and produce truly green energy with a simple flush. Significant other benefits are available to facilities that forge into the future with Captivator, including virtually eliminating problematic gritty sand particles from damaging equipment and eliminating costly thickening processes, all while using less real estate than today’s technology.

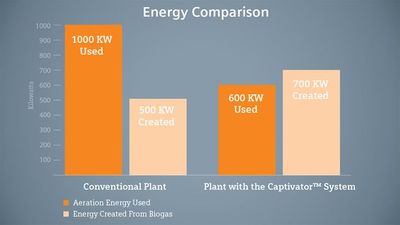

A step towards net zero energy consumption

A 100 ML/d conventional AS plant might use 1000 kW of energy for aeration and only produce 500 kW energy from biogas. Whereas, a plant with the Captivator System would use only 600 kW of aeration energy and could generate 700 kW energy from biogas.

Benefits include:

- 40% more biogas

- 40% less aeration energy

- 20% less capital

- Allows for more compact footprint on new installations

- Can be used in retrofit situations to expand the capacity of an existing installation.

The Captivator system video is included below:

What other types of new and novel products does Evoqua offer to help with wastewater loading demand and resource recovery?

While originally intended for phosphorous reduction to meet increasing regulation, Evoqua’s CoMag® System can also be applied to primary clarifiers to help rapid settling under storm conditions — nearly 30 times faster than conventional technology in the same footprint.

To see the difference for yourself, check out the new CoMag system video here:

Wastewater technologies are increasingly critical to water-scarce regions, where Evoqua’s Australian R&D and manufactured Memcor® membranes can be used in re-use applications, providing a much needed alternative source of water. It’s important to understand that the wastewater treated and discharged also affects our drinking water supplies when pumped from these same environments.

Innovative technologies need investment for development and without the investment and risk tolerance from municipalities, water and wastewater systems stay stagnant. Making any investment in water networks has a trickledown effect on user rates as well.

Please follow link for wastewater treatment information.

These poster pitches were presented at AWA’s Ozwater 2018 conference, which was held in Brisbane in May.

For further information, please contact: 1300-661 809 or info.au@evoqua.com.

Bega Cheese Upgrades DAF Plant for Excellent Results

Bega Cheese's Environmental Manager was presented with the challenge of upgrading the...

Gorman-Rupp EchoStorm static venturi aeration devices

The EchoStorm is a range of static venturi aeration devices installed in-line on the discharge...

Simple technology for solids removal from industrial and municipal wastewater

Simple, efficient, easily operated and maintained screening is the first and very critical stage...