Getting tired of your aging brush rotors?

Improve oxidation ditch performance while reducing maintenance and energy consumption within your existing plant footprint.

Aging brush rotors can be easily upgraded to low-maintenance and energy-efficient disc aerators. The unique disc aerator is made of durable high-density polyethylene incorporating moulded nodules and recesses to transfer oxygen and to provide superior mixing to brush systems. Because non-metallic OX disc aerators do not deteriorate or corrode like carbon steel brush rotors, the expected life of the system is at least 20 years. In contrast, brush rotors typically last an average of only five to 10 years.

Benefits of Disc Aerators:

- Last longer than steel brushes because non-metallic discs do not rust

- Deliver additional aeration capacity to handle increased influent loading

- Eliminate dead zones

- Eliminate dredging

- No additional baffles or mixers

- Reduce splashing that clogs mechanical components, lengthening service life

- Discs allow for improved mixing efficiency, lower energy, simpler operation, and less maintenance

- Disc aerators are easier on drives/motors

Increasing Treatment Capacity – Designed for Maximum Oxygen Transfer

The bigger and completely redesigned 1.67m diameter OX disc aerator doubles the amount of oxygen transferred by the original Orbal system disc aerator or any brush-type rotors. This means that the same amount of oxygen can now be delivered with fewer discs, which reduces maintenance, construction and capital costs. It also allows facilities to increase capacity if they replace their existing brush rotors with new OX disc aerators.

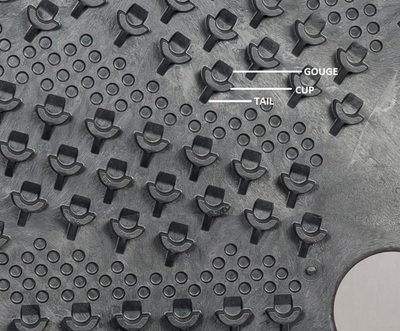

The nodules on the original Orbal system disc have been redesigned on the new OX disc aerator to dramatically increase the amount of oxygen transfer. The pyramid design in the original disc has been changed to a cup design. A gouge also has been added in front of each cup to increase the surface area of each nodule, which drives the oxygen transfer rate. These design changes have nearly doubled the face surface area on the nodules. The new design doubles aeration capacity with an SOTR of up to 2.2 kg/h/disc while maintaining oxygen transfer efficiency.

Process Operation and Efficiency Improvements

Operators also prefer OX disc aerators because they generate excellent oxygenation within the basins. Dead zones are eliminated because the OX disc aerators provide more uniform mixing throughout the entire basin. With better mixing capabilities, the OX disc aerator can operate at lower speeds that require less power. In fact, OX disc aerators can use up to 40 percent less power than conventional brush rotors if basins are operated in series.

Reduced Maintenance and Enhanced Durability

Operators like OX disc aerators because they slice through the water, rather than striking it, which results in substantially less operational noise and eliminates messy excess splashing that clogs mechanical components and requires constant clean-up. And OX disc aerators may require fewer drives, which reduces noise, capital expenditures and maintenance. Although the original Orbal system disc has a proven record of durable, reliable performance with nearly 1,000 installations worldwide, the all-new OX disc aerator has been designed for even greater strength. In fact, finite element analysis (FEA) tests demonstrate that stress is more evenly distributed over a greater surface area in the OX disc aerator, compared to the original disc.

At Evoqua, we have more than 40 years of expertise in both brush rotors and disc aerators. Evoqua is the OEM for Passavant Mammoth brush rotors. We also pioneered the disc aerator in the 1970s. So, we can replace your existing brush rotors or upgrade your ditches with OX disc aerators.

To learn more about the Orbal system and OX disc aerators visit www.evoqua.com/orbal. For enquiries in Australia call 1300 661 809 or email sales.au@evoqua.com.

Bega Cheese Upgrades DAF Plant for Excellent Results

Bega Cheese's Environmental Manager was presented with the challenge of upgrading the...

Gorman-Rupp EchoStorm static venturi aeration devices

The EchoStorm is a range of static venturi aeration devices installed in-line on the discharge...

Simple technology for solids removal from industrial and municipal wastewater

Simple, efficient, easily operated and maintained screening is the first and very critical stage...