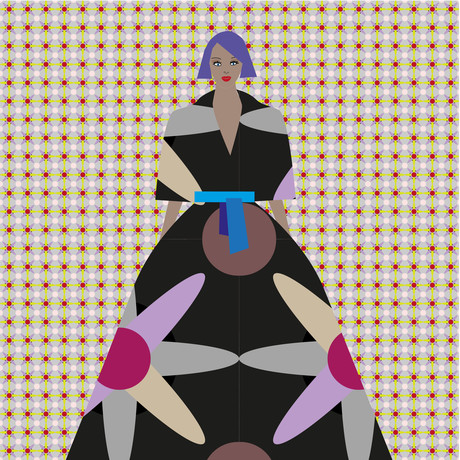

Re-dressed for success

The circular economy is the new black for the Australian fashion industry, with Adelaide hosting a sustainable fashion event in September which was aimed at reducing the sector’s environmental footprint.

Hosted by the University of South Australia (UniSA), the Redress Design Award Fashion Academy focused on ways to reduce clothing and textile waste and help stem the ‘disposable’ throwaway culture endemic among clothes buyers.

Fashion students and emerging designers from across Australia spent the day workshopping ideas and techniques to combat the mountain of material waste that ends up in landfill, according to organiser Dr Alison Gwilt.

Dr Gwilt, an Adjunct Senior Research Fellow in UniSA’s School of Arts, Architecture and Design, said the global focus on the environment and the rise of the circular economy is helping to reshape the fashion world.

“The ‘take, make and dispose’ model of production is no longer fit for purpose. Instead, we are now adopting a circular economy that is economically and environmentally sustainable and where we can regenerate and recycle products and materials,” Dr Gwilt said.

The event organiser, Redress, is a Hong Kong-based not-for-profit company that has spent the past decade working with fashion designers to reduce product waste. Initially focused on Asia, it is now a global enterprise and this year has opened its sustainable fashion competition to Australian designers for the first time.

“The challenge is to design a fashionable garment that has no waste involved in producing it,” Dr Gwilt said. “This entails engineering their patterns to use as much of the material as possible.”

A 2017 YouGov report found that 40% of Australians have thrown away unwanted clothing rather than trying to repair or recycle the garments and 75% have tossed out clothes in the past year.

The throwaway culture is harming not just the environment — with 500,000 tonnes of textiles and leather sent to landfill in Australia — but creating a huge economic cost, with 10% of materials wasted, Dr Gwilt said.

The good news is that some global clothing retailers are heeding the environmental message and embracing the ‘slow fashion’ movement. Patagonia, an outdoor clothing designer, was one of the first to produce fleeces made from recycled plastic water bottles, which involves crushing the plastic into chips and heating it to form a yarn that is knitted into a fleece material.

Meanwhile, the Swedish multinational clothing store H&M encourages its customers to drop off unwanted clothes for recycling in return for a voucher. To date, they have collected more than 17,771 tonnes of textiles — the equivalent of 89 million t-shirts. These clothes are recycled as insulation material, carpet underlay, stuffed toys or even shoe insoles, among many other things.

“There are a whole lot of business models coming out of the global fashion industry and Australia is starting to catch on,” Dr Gwilt said.

“As an educator, my job is to interrupt the linear model and produce graduates who are focused on eliminating waste in the fashion industry.”

How Sydney's OS Passenger Terminal slashed its waste costs

Veolia has delivered a custom-designed solution that cut the Overseas Passenger Terminal's...

Sludge treatment: a weighty issue

Sludge dewatering might not be the most glamorous process, but it is a vital part of ensuring...

Getting closer to a circular economy for plastics

A new process that vaporises hard-to-recycle plastics in order to make recycled plastics has been...