Nine million tyres to disappear

Used Tyre Recycling Corporation (UTRC), a national tyre recycler based in Stawell, Victoria, has just purchased a $250,000 shredder with which to dispose of the town’s stockpile of nine million tyres.

Dr Matthew Starr, CEO of UTRC, said the corporation is working well with authorities such as the Environmental Protection Authority, Country Fire Authority and Powercor and has invested considerable resources to help make the stockpile site more secure and reduce its fire risk.

“Within the next 12 months, we expect to have invested $10 million in infrastructure in Stawell,” Starr said, referring to the company’s state-of-the-art recycling plant. “We are very serious about reducing the stockpile and as soon as our processing plant is operational, we will be working 24 hours a day, seven days a week to do just this.

“Our first step is to get the shredder installed and three-phase power connected to the site. We are pleased that the Northern Grampians Shire Council is supporting us to facilitate the permits needed for this to happen.”

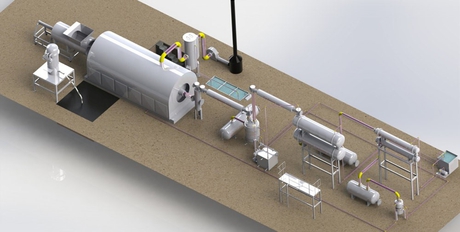

The plant will employ technology which is based around a patented tyre pyrolysis technique that was developed in Canada and is now owned by UTRC. The principle of the pyrolysis plant is a vacuum chamber that heats shredded rubber to 900°C. The process produces an abundant supply of recycled resources primarily comprising carbon black and, through an oil distillation process, auto-quality diesel.

“The technology is so good that the activated carbon black we produce approaches virgin carbon black material, and we plan to use the diesel on-site to fuel vehicles and other engines,” Starr said. “Importantly, there will be zero emissions and minimal noise from our operation.”

UTRC is in talks with overseas buyers for the carbon black, which is a valuable resource that can be used in myriad industries for scores of applications. One potential emerging use is for anodes and cathodes in energy storage solutions such as the latest technology batteries.

Starr said the company is addressing both short-term and long-term issues with its investment in Stawell.

“First up, our priority is to eliminate the stockpile,” he said. “But while this is happening we are also in the process of establishing funnels of tyre supply from NSW [and] Queensland, and of course we want our site to be a focal point for the majority of used tyres in Victoria.”

Starr added that the benefits to the Stawell community — where the youth unemployment rate sits at 17% — will be “enormous”.

“As soon as we start shredding we will employ eight full-time workers, ramping up to 50 full-time staff when the complete processing plant is operational,” he said.

How Sydney's OS Passenger Terminal slashed its waste costs

Veolia has delivered a custom-designed solution that cut the Overseas Passenger Terminal's...

Sludge treatment: a weighty issue

Sludge dewatering might not be the most glamorous process, but it is a vital part of ensuring...

Getting closer to a circular economy for plastics

A new process that vaporises hard-to-recycle plastics in order to make recycled plastics has been...