Programmable cement particles create stronger structures

US scientists have decoded the kinetic properties of cement and developed a way to ‘program’ the microscopic, semicrystalline particles within.

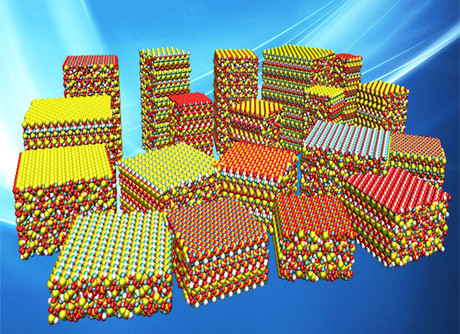

Developed at Rice University and published in the Journal of Materials Chemistry A, the process turns particles from disordered clumps into regimented cubes, spheres and other forms that combine to make the material less porous and more durable. The technique may lead to stronger structures that require less concrete, making them more environmentally friendly.

Lead author Rouzbeh Shahsavari and his colleagues decoded the nanoscale reactions — or ‘morphogenesis’ — of the crystallisation within calcium-silicate hydrate (C-S-H) cement that holds concrete together. Previous techniques to create ordered crystals in C-S-H had required high temperatures or pressures, prolonged reaction times and the use of organic precursors, but none were efficient or environmentally benign.

The Rice researchers created their cubes and rectangles by adding small amounts of positive or negative ionic surfactants and calcium silicate to C-S-H and exposing the mix to carbon dioxide and ultrasonic sound. The crystal seeds took shape around surfactant micelles within 25 min.

Once the calcite seeds formed, they triggered the molecules around them to self-assemble into various shapes that can pack more tightly together in concrete than amorphous particles. Carefully modulating the precursor concentration, temperature and duration of the reaction varied the yield, size and morphology of the final particles. Decreasing the calcium silicate yielded more spherical particles and smaller cubes, while increasing it formed clumped spheres and interlocking cubes.

“The seed particles form first, automatically, in our reactions, and then they dominate the process as the rest of the material forms around them,” Shahsavari said. “That’s the beauty of it. It’s in situ, seed-mediated growth and does not require external addition of seed particles, as commonly done in the industry to promote crystallisation and growth.”

The new technique has several environmental benefits, Shahsavari said. “One is that you need less of it [the concrete] because it is stronger. This stems from better packing of the cubic particles, which leads to stronger microstructures. The other is that it will be more durable. Less porosity makes it harder for unwanted chemicals to find a path through the concrete, so it does a better job of protecting steel reinforcement inside.”

How to navigate Australia’s new climate regulations

Australia’s new mandatory climate reporting regulations are set to take effect next year,...

A concrete use for carpet fibres

Australian engineers have come up with an unexpected use for discarded carpets: as a means to...

COP29: finance, a "crucial" opportunity and a seat at the table

Leaders and diplomats from around the world are descending on Baku, Azerbaijan, this month for...