Simpler solar cell design removes the need for doping

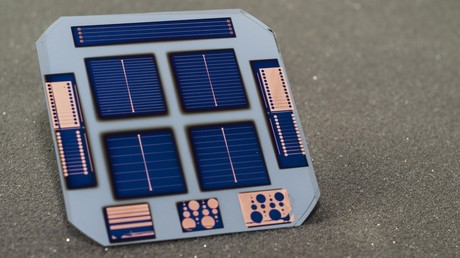

An international research team has developed a new silicon solar cell, said to promise cheaper manufacturing processes and better power output in just seven steps. Published in the journal Nature Energy by US, Swiss and Australian researchers, the breakthrough saw the application of a new mix of materials to a standard solar cell design.

The goal of the research was to eliminate the need for a process called ‘doping’, which introduces foreign atoms to a solar cell’s crystalline silicon wafer in order to enhance electrical conductivity. These atoms either have electrons to spare when they bond with silicon atoms or alternatively, generate electron deficiencies — so-called ‘holes’.

The two types of dopant atoms are required at the electrical contacts to regulate the way that electrons and holes travel across a solar cell so that sunlight is efficiently converted to electrical current flowing out of the cell. However, the method can also make a solar cell device’s processing more complicated and cause losses in performance.

In contrast to this process, the researchers took the crystalline silicon wafer and applied layers of dopant-free amorphous silicon for surface passivation. They then applied ultrathin coatings of a material called molybdenum oxide at the sun-facing side of the solar cell and lithium fluoride at the bottom surface. The two layers act as dopant-free contacts for holes and electrons, respectively.

“Moly oxide and lithium fluoride exhibit extremely high and low work functions, respectively, which make them ideal for dopant-free electrical contacts,” said lead senior author Professor Ali Javey from UC Berkeley and the Berkeley Lab. The difference means that when sunlight hits the silicon and creates an electron-hole pair, the electron is drawn to the lithium fluoride, while the hole goes the opposite way, which creates an electric current.

The dopant-free silicon cell — referred to as a DASH cell (dopant-free asymmetric heterocontact) — promises a low energy footprint because it is manufactured below 200°C, in contrast to conventional doped cells which are made at above 800°C. The cell also does not require the often toxic chemicals used to dope conventional materials.

“If you look at the architecture of the solar cell we made, it is very simple,” said lead author James Bullock, a PhD student who was visiting the Berkeley Lab and UC Berkeley from The Australian National University (ANU). “That simplicity can translate to reduced costs.”

While dopant-free silicon cells have never before exceeded 14% efficiency, the new cell has an efficiency approaching 20% — close to that of a doped cell.

“[And] there is nothing to say we can’t get to the world-record efficiencies, over 25%, using this approach,” said co-author Professor Andres Cuevas from ANU.

Solar cell achieves world record for efficiency

University of Queensland researchers have set a world record for solar cell efficiency with...

Boral secures grant for cement kiln carbon reduction

The project will reduce process emissions from cement clinker manufacturing by up to...

Vast secures grant to progress SA Solar Fuels project

HyFuel Solar Refinery, a subsidiary of Vast, has been awarded $700,000 through the ASLET...