Monash researchers use microalgae to make clean hydrogen

An international research team has used microalgae to produce hydrogen and methane with a significantly reduced carbon footprint.

The researchers, from Monash University’s Department of Chemical Engineering, the IITB-Monash Research Academy Mumbai and The Indian Institute of Technology’s Department of Chemical Engineering, used reactive flash volatilisation (RFV) gasification technology on microalgae to produce hydrogen — a process reported to reduce greenhouse gas emissions by 36% compared with steam reforming of methane gas, which is the current best practice for hydrogen production.

RFV is a gasification process that uses oxygen and steam that converts biomass or fossil fuel-based carbon materials into gases. Published in the Journal of Cleaner Production, the researchers performed the RFV of microalgae using temperatures ranging from 550–650°C using steam as the gasifying agent. This meant the dewatering or drying of microalgae wasn’t required and significantly reduced energy consumption.

It is estimated that if additional renewable energy processes such as hydro-electricity were integrated with the researchers’ hydrogen production process, carbon emissions could drop by as much as 87%.

Microalgae production does not currently meet commercial demand; however, microalgae cultivation for energy applications could provide additional revenue streams for rural communities, potentially making them self-sufficient, the researchers say.

“Hydrogen and methane are clean sources of fuel and green chemical synthesis only if they are produced from renewable resources. At present, 96% of hydrogen and all methane is produced using non-renewable resources,” research co-author Associate Professor Akshat Tanksale, from Monash University, said.

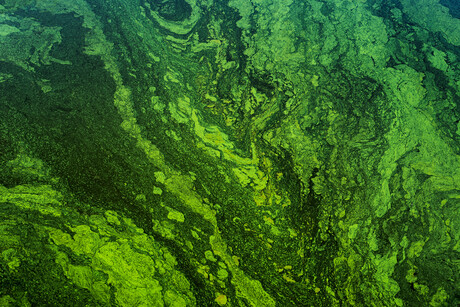

“Microalgae as a feedstock is attractive due to its high carbon dioxide fixation efficiency, growth rate, photosynthetic efficiency, ability to grow in brackish water — like rivers and lakes — and the ability to cultivate it on land not suitable for agriculture.

“Water and renewable electricity integration with microalgae harvesting can bring down the costs and increase the sustainability of hydrogen production from this process.”

Dr Yogendra Shastri from the Department of Chemical Engineering at IITB-Monash Research Academy Mumbai said climate change concerns have led to an increasing push for cleaner energy options, and microalgae could be a potential candidate to produce renewable fuel.

“Hydrogen is acknowledged as clean fuel since it doesn’t lead to the emission of greenhouse gases when used. However, the production of hydrogen also needs to be sustainable,” Dr Shastri said.

“Biodiesel production from microalgae is limited due to low lipid extraction efficiency — less than 20% — and the high cost of microalgae harvesting and drying.

“Furthermore, microalgae-based hydrogen and methane production haven’t yet been commercialised due to expensive pre-treatment, such as harvesting, drying and lipid extraction; low carbon conversion efficiency; and tar accumulation.”

Using India-based JSW Steel (the funding agency for this research) as a case study for their source of CO2 for microalgae cultivation, the research team estimated just under 12,800 kg/h of microalgae would be available for hydrogen production at a rate of 1240 kg/h.

While the costs to develop infrastructure to cultivate microalgae and then refine it into hydrogen and methane are expensive, the overall return on investment in the long term could make hydrogen and methane cost-effective and environmentally friendly fuel sources.

“Assuming a market price of $10/kg for hydrogen compressed to 700 bar pressure, the payback period for hydrogen production was 3.78 years with nearly 25% investment return. Moreover, the life cycle climate change impact was 7.56 kg of carbon dioxide for every kilogram of hydrogen produced,” Dr Pratik Gholkar, research student at IITB-Monash Research Academy Mumbai, said.

“This is an exciting look into the resources and technology available to the world in our quest to reduce the use of fossil fuels and drastically cut the amount of carbon emissions.”

Sustainable organic batteries for future energy storage

A rechargeable proton battery being developed by scientists at UNSW Sydney has the potential to...

CSIRO's solar venture secures $15 million funding

FPR Energy, a new venture from CSIRO, has secured $15 million in seed funding.

Aust partnership leads to solar-powered canola

Riverina Oils, a NSW canola oil producer, has partnered with Australian renewable energy retailer...