Screw blower or turbo blower?

Friday, 27 March, 2015

Positive displacement (PD) blowers, used for aeration in wastewater treatment for over a hundred years, should no longer be used due to their low efficiency and high energy demands. Wastewater treatment facilities now choose among modern technologies: turbo blowers, rotary lobe compressors (also known as hybrids) and positive displacement screw blowers. All these models promise energy efficiency and energy savings.

This article will compare positive displacement screw blowers and turbo blowers. Both claim 35% more efficiency vs PD blowers, but which one to choose?

Blower type

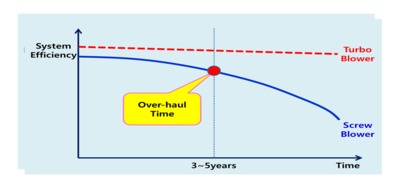

Rotary screw blowers are positive displacement blowers with precision timing gears that maintain minute clearances between two intermeshing oil-free screw elements that never touch. However, the screw blower has contact parts such as gear and bearings in the blower package. These contact parts are wearing and tearing and the gap between the screws is getting larger to leak the air. The leakage is getting larger as time of operation gets longer.

The rotary screw air ends are also coated with Teflon, which deteriorates after 2-3 years of operation and means loss of airflow delivery, as illustrated in Figure 1.

In centrifugal blowers, also called turbo blowers, the energy is transferred from a rotating shaft to air or gas. A pressure rise is achieved by adding kinetic energy to a continuous flow of air through the rotor or impeller. A turbo blower differs from a turbo compressor by the lower pressure ratio, with the compressor’s being above 2.5. A centrifugal compressor increases pressure up to several hundred kPa, while a centrifugal blower performs in the middle range, up to 200 kPa.

Bearings

Rotary screw blowers use cylinder roller bearings - the earliest known type of rolling element bearing, dating back to at least 40 BC. As they operate in a hot environment with high load, they tend to wear and tear with time and normally need replacement after 3-5 years of operation, associated with major repair costs.

The air-bearing design used in turbo blowers utilises the speed of the air to avoid the contact of the surfaces and, as a result, is free from friction and wear. It can only be used for high-speed applications. Bump-type airfoil bearings, developed by NASA and used in some of the models of turbo blowers, have an advantage over the leaf-type air bearings with their higher load capacity. Their durability is measured not in the hours of operation but in the number of start-ups and turn-offs. Having been tested for 20,000 start/stops, the lifetime of airfoil bearings will be many years of operation. Moreover, blower efficiency does not decrease with time.

Motor

Rotary screw blowers are provided with standard induction motors, which lose their efficiency by 50% at lower operating speeds.

Turbo blowers use high-efficiency, high-speed motors called PMSM (permanent magnet synchronous motors) utilising permanent magnets, providing higher power output to a given frame size. Thanks to direct connection with the impeller, no power is lost during transmission. PMSMs comply with the Super Premium Efficiency standard IE4, which was published by the International Electrotechnical Commission in 2014. The efficiency advantage of a PMSM compared to an induction motor would be 5-8%, as illustrated in Figure 2.

Controller

Screw blowers offer their proprietary microprocessor controls, which restrict customers in their choice and flexibility. Turbo blower manufacturers offer major brands of Allen-Bradley or Siemens controllers for reliability and ease of servicing/replacement, as well as for the ability to amend running parameters.

Range

Screw blower operating range is limited, with the power up to 355 kW, pressure up to 120 kPa and the flow capacity up to 154 m3/min. Turbo blowers’ flow capacity is up to 700 m3/min, pressure is up to 200 kPa and power is up to 600 kW. A much larger range of flow and pressure can be suitable for small to very large WWTPs.

Total efficiency

A blower package is defined as the complete system consisting of a blower (compressor), motor, inverter (variable frequency drive), blow-off valve, controller, inlet filter and cooling system, assembled and operating inside the enclosure.

‘Wire to air’ (total) power consumption is the total energy used to produce the required flow and pressure for any particular application. It includes all power losses in the motor, variable frequency drive, inlet filter, guide vane, valves, cooling system, loss by compressor suction temperature rise and pressure drop. The complete blower system must be tested for efficiency, as it’s the ‘wire to air’ power consumption that is reflected in the electricity bill.

The overall wire to air efficiency and the total ownership cost of a high-speed turbo blower is superior to rotary screw technology due to the following facts:

- Centrifugal compression efficiency is higher than rotary screw compression.

- Turbo blowers do not lose capacity, whereas the screw blowers do.

- The package efficiency of turbo blowers is superior to screw blowers due to the PMSM, direct transmission without any gear/bearing losses and no loss of capacity due to coating wear.

- Turbo blowers provide major savings in ongoing maintenance costs - users need only replace the air intake filters, whereas screw blowers need a major overhaul after 2-3 years.

Verdict

The turbo blower outperforms the centrifugal blower due to its technical characteristics; however, the choice depends on multiple factors, including the size of the plant. Talk to the experts at Hurll Nu-Way to make up your mind.

Fluoride boosts water-processed perovskite solar cells

Queensland University of Technology has developed a water processing method to fabricate more...

Multibuild solar installation delivered at City of Playford

Trinasolar partnered with Venergy Solar to deliver a multibuild solar installation across the...

Oracle assists major distributor in clean energy transition

Essential Energy, an electricity distributor in Australia, is said to have modernised its...